Master Your Performance With DSI

downhole solutions

Tailored for Operational Needs

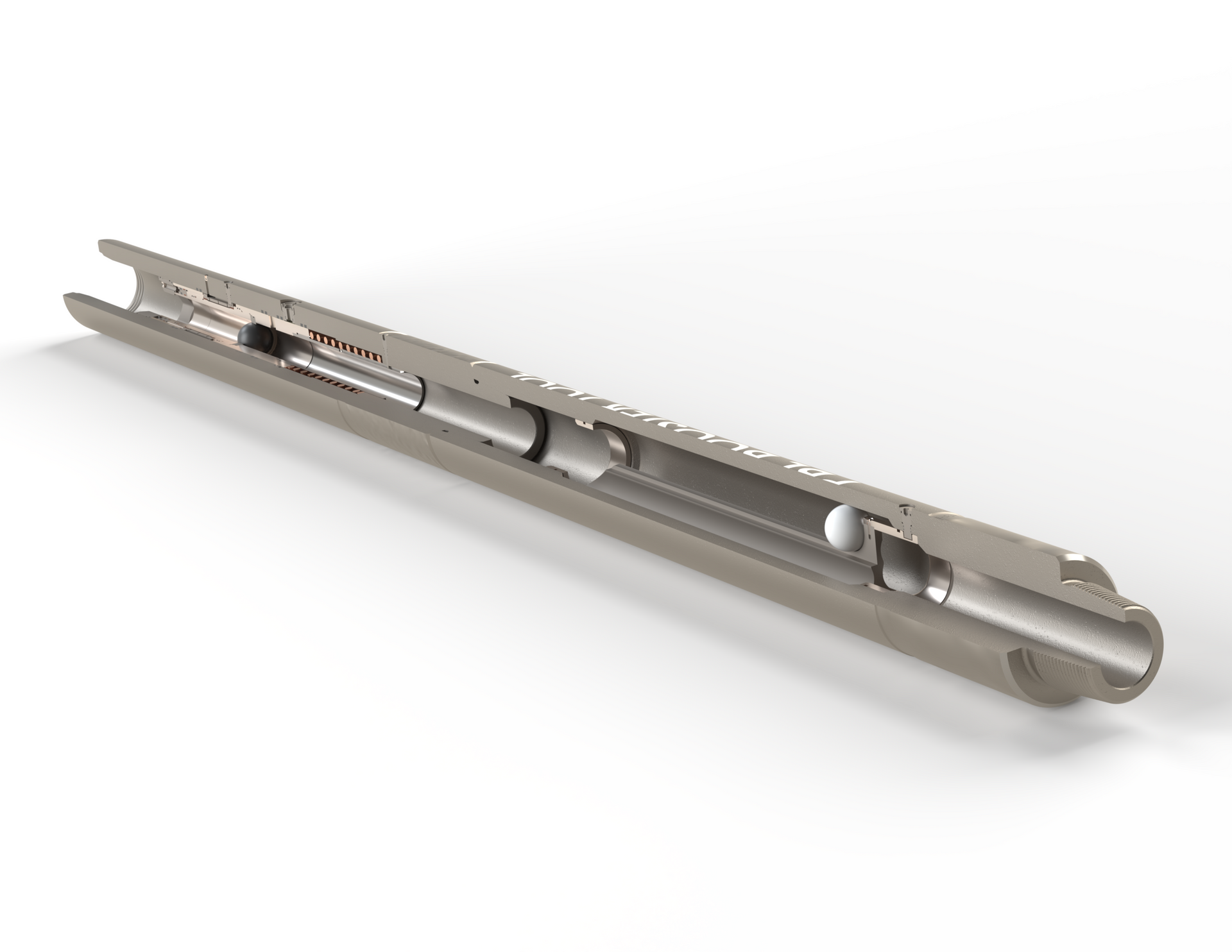

In addition to the patented PBL system, DSI offers multiple systems and activation mechanisms to meet varying operational requirements. For most applications, the patented ball activation method is the simplest and most reliable solution, providing easy and efficient tool operation. This flexibility ensures operators can select the activation option best suited to their specific needs, enhancing the versatility and performance of the tools across a wide range of drilling applications.

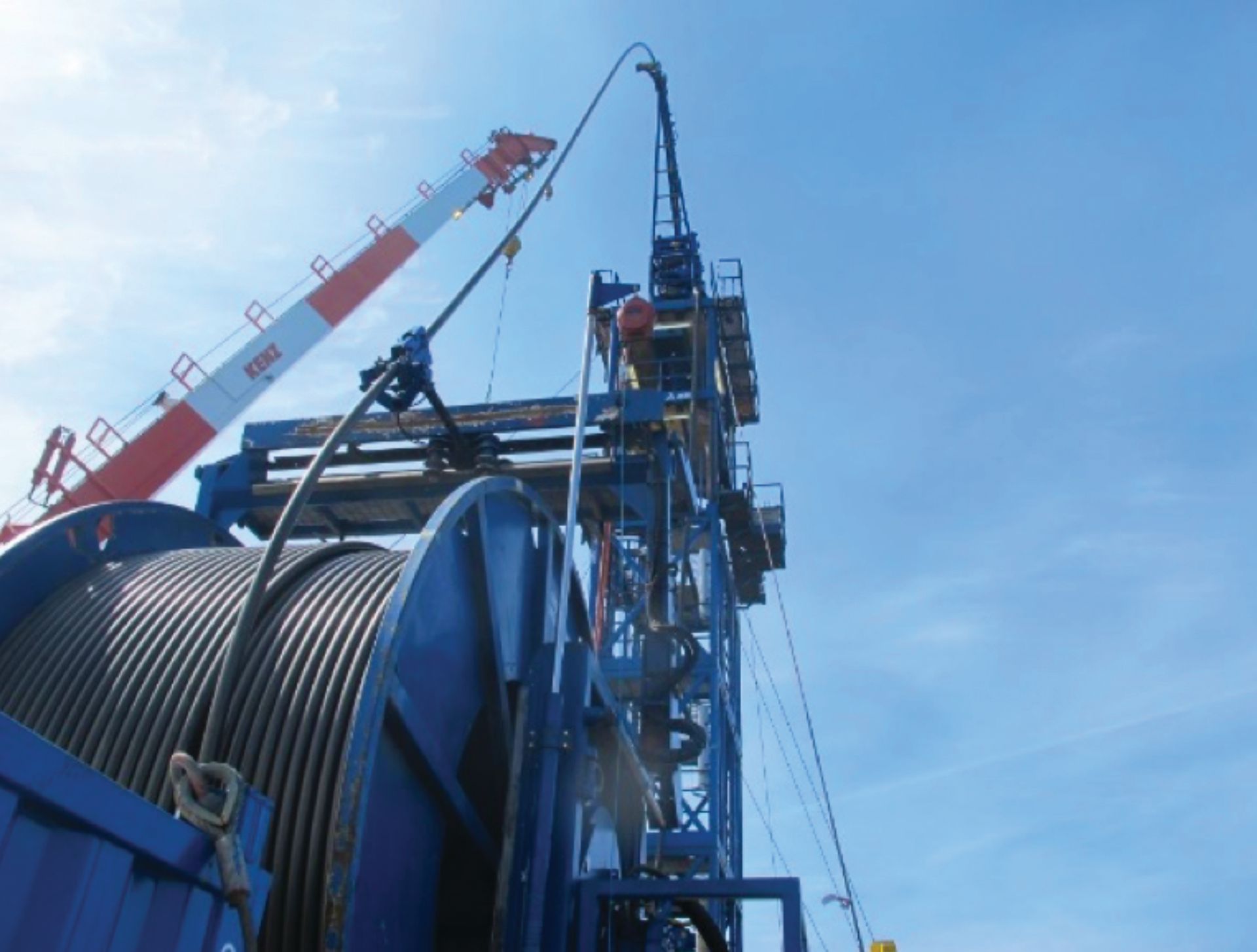

Tailored for Coiled Tubing and Through-Tubing Applications

The Slimhole PBL® tool is specifically designed for coiled tubing and through-tubing operations, offering all the capabilities of the Standard PBL® tool in a more compact form. Featuring a three-port configuration, it delivers industry-leading TFA for superior hole cleaning, whether in conventional or unconventional applications such as the plug-and-perf technique.

By enhancing hole-cleaning efficiency in scenarios where pump rates are constrained by high pressure, the PBL® tool eliminates the need for short trips. This not only reduces fatigue on coiled tubing and saves rig time but also significantly extends its operational life, making it an ideal choice for demanding wellbore conditions.

Enhanced Split-Flow Efficiency while Drilling

The Booster Tool is designed for split-flow applications, offering multiple nozzle configurations to direct part of the drilling fluid through the tool to the BHA, with the remainder flowing through side ports into the annulus

This design enables:

- Ideal flow rates through sensitive components such as the MWD/LWD, rotary steerable systems, or drilling motors

- Prevention of excessive hydraulic power (HSI) around the bit, minimizing wellbore erosion and steering difficulties

- Lower surface pump pressure and ECD at the same flow rate.

- Higher flow rates at same surface pump pressure

- Increased annular velocities and better hole cleaning.

- At circulating cycles, increase total flow rate while still circulating through and cooling sensitive BHA components

Optimized Cleanout Efficiency

The PBL® Multiple Activation Jetting Tool is an innovative addition to the standard BHA, designed to streamline cleanout operations and minimize rig time. By incorporating this tool, operators can efficiently clean inside the blowout preventer (BOP) and riser without the need for additional trips, significantly reducing operational costs.

This tool features an outer spiral sleeve equipped with up to 30 nozzles, enabling high-velocity jetting with 360° coverage. This ensures thorough cleaning without the need to rotate the drillpipe, enhancing operational efficiency and making it a valuable addition to any BHA configuration.

Enhanced Retrievability and Versatility

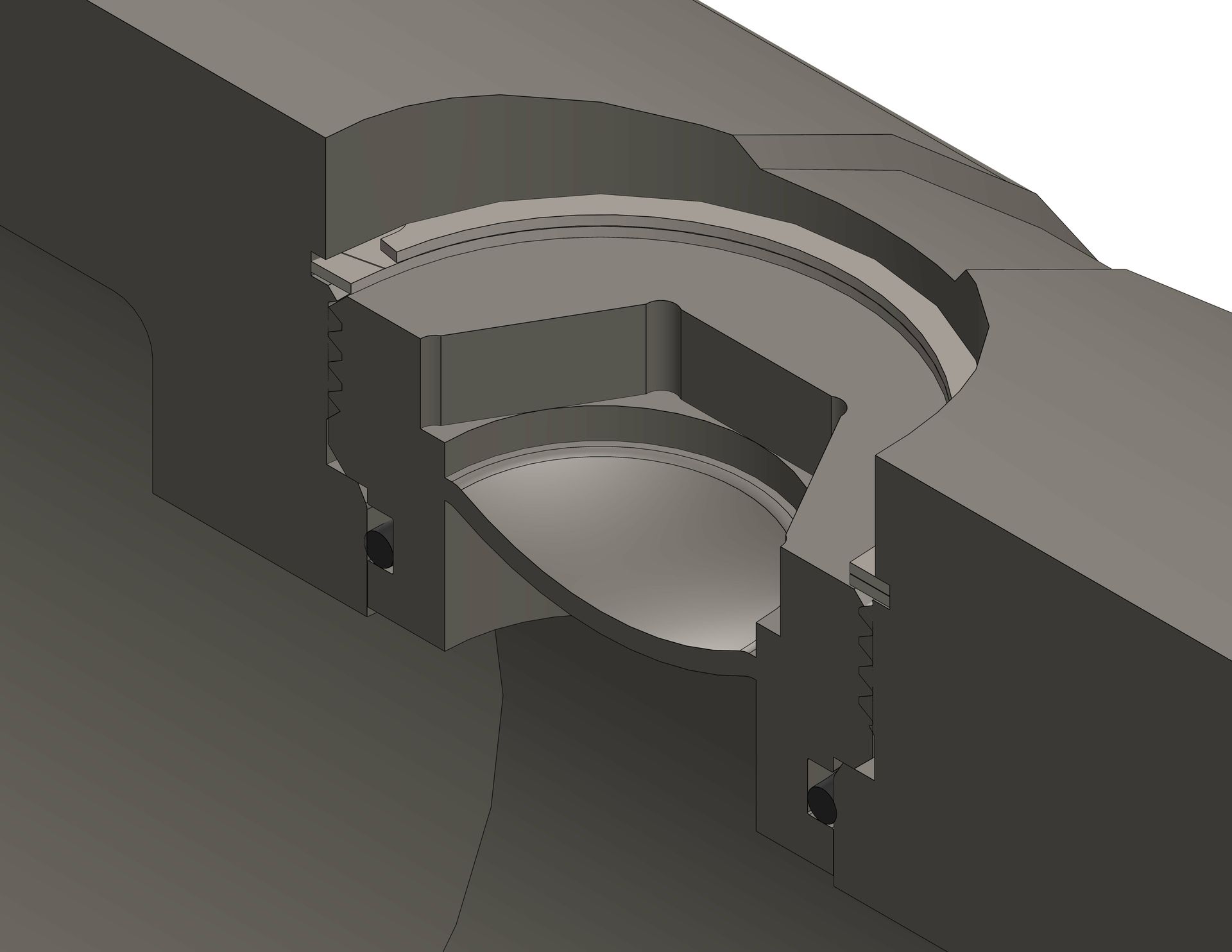

The SSBB System is designed for drilling operations that require the retrievability of Radioactive (RA) sources from the BHA below the circulation sub. While maintaining the same functionality as the standard PBL® Tool, the SSBB System introduces unique features that enhance its versatility and operational efficiency.

The SSBB tool features a significantly larger internal ID and eliminates the need for a ball catcher cage. This design not only facilitates the retrieval of components from below the SSBB tool but also allows for an unlimited number of cycles when opening or closing the tool, providing greater flexibility and operational control.

The SSBB System is the ideal solution for applications requiring both the reliability of the PBL® tool and the added capability of maintaining through-bore, making it a valuable asset in complex drilling environments.

The ‘Differential’ Makes the Difference

DSI’s HydraFlow® is a cutting-edge, hydraulically activated tool, built on the legacy of the renowned PBL Through-Tubing multiple activation bypass tool.

Designed for Coiled Tubing Drilling & Completion operations, HydraFlow® offers unlimited cycling without the need for balls, darts, RFID chips, or electronic pulses. Its differential activation and de-activation system ensures smooth, instant activation without any delay, while maintaining a full bore.

With the ability to bypass 100% of the flow , HydraFlow® ensures optimal hole cleaning by isolating flow through today’s sophisticated downhole tools, thereby reducing the pressure loss in the BHA ; achieved simply by cycling the pumps , without the need of any activation medium. These versatile features make HydraFlow® an ideal solution for maximizing efficiency and performance in complex coil tubing operations.

Ensuring Circulation and Well Control

Integrating the HPHT Burst Disc into the lower section of the PBL® Multiple Activation Bypass System provides an additional layer of protection during drilling operations. Positioned in the lower section of the tool, the Burst Disc is designed to address common challenges such as BHA or bit pack-off, offering extreme differential pressure capability on both sides.

In the event of a pack-off or circulation loss, the Burst Disc creates an alternate flow path, restoring circulation. The operator can then regain full control of the well through the activation of the PBL® tool