PBL® Bypass System – Passing Thru Casing ID Restrictions/Collapsed Points – Thru-Tubing Services Argentina

Challenge

One of the problems associated with the completion of extended horizontal wells is the presence of collapsed casing. This aspect makes it harder to clean the well, mainly where it has been completed with the plug and perf system. Our client asked us to propose a solution that would allow the BHA to go through the collapsed points and rotate the plugs as much as possible to the drift.

The casing dia. was 5″/21.4# (101.6 mm drift) and according to the multi-finger tool, before the first plug, there were 4 collapsed zones with different geometric shapes, where the smallest pass thru diameter was 90 mm. Beyond the collapsed zones, there were still 17 plugs to be drilled.

Solution

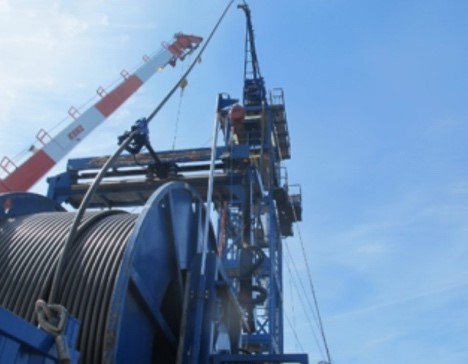

The BHA was proposed with a 2-7/8” DSI-PBL and a Bi-Centre Mill Tool, which had an 87 mm pass thru diameter and an orbital pass thru diameter of 100.5 mm. The use of the PBL was essential to perform the operation without fatiguing the BHA and damaging the CSG.

- During the operation, the following sequence was performed:

- Mill 2 plugs and activate PBL, circ bottoms up + wiper trip to vertical section.

- Repeat until reaching 6th plug.

- Pull out of hole and change BHA completely.

- Repeat 3 times until finish milling the remaining 17 plugs and reach TD.

By activating the PBL at the collapsed zones, it was possible to pass thru with the problem points without mill rotation and yet with full circulation above the BHA.

Results & Benefits

The rotating operation was concluded successfully, reaching the main objective of milling the 17 plugs which were beyond the collapsed points and reaching TD. The use of PBL not only made it possible to reduce BHA fatigue with the use of a bicentric mill, but also to improve hole cleaning. This was fundamental because the cuttings generated by the bicentric mill are larger and geometrically different from a conventional flat mill. The maximum pumping rate with the activated PBL is 3.8 bpm. This case has become another completions program essential point for the customer, wherever the scenario is encountered.