PBL® Bypass System Saves Time and Money for a Major Norwegian Operator During Coring Operations

Application

During coring operations for a major Norwegian operator in the northern Norwegian Sea, the challenge was to minimize circulating time – and more crucially maintain the core quality – when sweeping the hole clean following the completion of coring operations. During standard coring operations, the flow rate is limited by the TFA of the core barrel and the need to preserve the core sample.

Solution

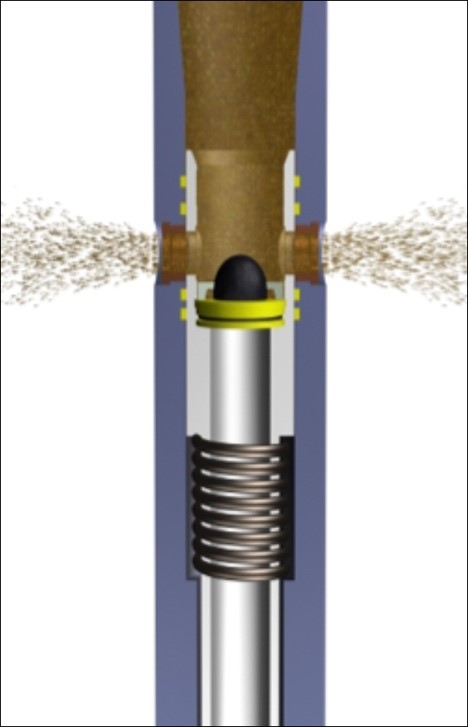

DSI supplied a 6 3⁄4” Multi-Cycle PBL Circulation Sub, which was positioned in the BHA 30.25 m above the core head. The PBL tool contained a specially designed ‘pass-thru’ ID to allow the coring activation ball to be safely used. Placing the PBL tool above the core head and core barrel allows for 100% fluid bypass when the tool is activated, thus enhancing annular flow rates while preserving the core. When activated, the PBL tool will allow a 70 % increase in flow rate within the annulus, thereby minimizing circulating time when the hole is swept clean.

Results & Benefits

- Enlarged PBL tool ‘pass-thru’ ID allowed coring activation ball to be safely used on multi-runs.

- Crucially the core sample was 100% preserved within the core barrel – minimizing core runs.

- The PBL tool allowed increased flow rates from 1,000 l/min (265 gpm) to 1,700 l/min (450 gpm).

- Eliminated approx. 2 hours of circulating time PER CORE RUN resulting in savings of USD 25,000 per run.